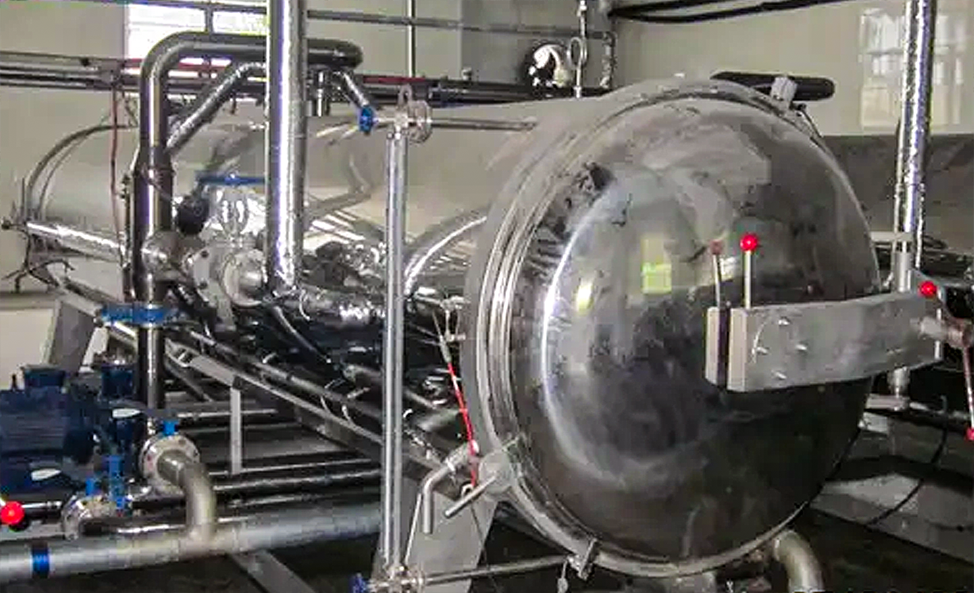

The device is used to recover sulfur from acid gas containing hydrogen sulfide produced in the refining process, and adopt appropriate process methods to realize clean production, turn harm into profit, turn waste into wealth, reduce pollution, and protect the environment. Meet product quality requirements, reduce corrosion, and realize long-term safe production of devices.

challenge:

The sulfur recovery unit uses H2S as the raw material to produce sulfur. Therefore, H2S is a substance with a wide distribution and high concentration in the sulfur recovery unit. It is poisonous and harmful, which seriously threatens personal safety.

product:

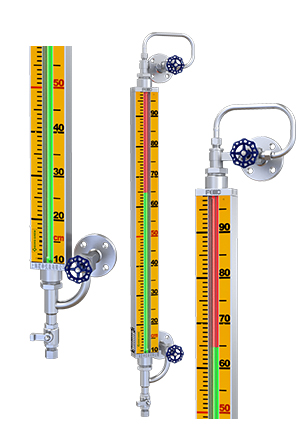

● UHZ-517 series magnetic flap liquid level gauge

UHZ-517 series magnetic flap liquid level gauge is a new type of on-site display instrument. The product has the characteristics of simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safety and reliability, and convenient installation, use and maintenance. This product is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, pharmaceutical, papermaking, environmental protection and other industries to provide on-site indication of the liquid level in various storage tanks, tanks and other containers, and the company’s production All kinds of liquid level transmitters and liquid level switches realize the automatic process control and measurement of various industries.

Features:

● Simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safe and reliable, easy to install, use and maintain.

● The float is made of 304, 316 (L), 321, PP, PVC, PTFE and F46 materials, and the float has good high temperature resistance, which can reach 520°C.

● The welding process meets the requirements of PED welding process. The outer cylinder is made of 304 and 316L materials, and the maximum pressure resistance can reach 25Mpa.

● Optional local indication type, remote transmission type, and liquid level alarm type.

● According to the needs of customers, through various types of production, it can be applied to various working conditions.

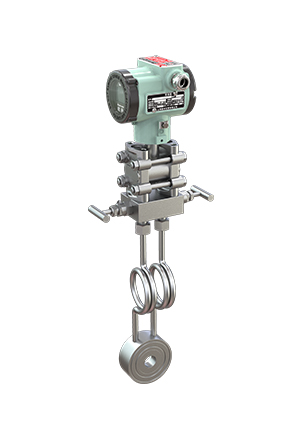

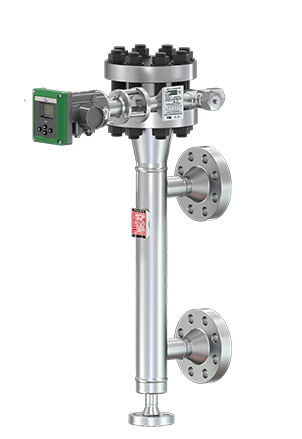

● LC series intelligent displacer liquid (interface) level transmitter

LC series displacer type liquid level gauge is designed according to the principle of Archimedes buoyancy, and is used to measure liquid level, interface and density of liquid. It has high measurement stability, especially suitable for liquid level/interface measurement occasions with small range, high temperature, high pressure, and low density, and can meet the interface measurement with small medium density difference. The transmitter can conveniently perform remote configuration and management (monitoring) of the transmitter through the HART communication protocol, using a PC or a general-purpose handheld terminal, and can also be operated with conventional local keys.

Features:

● Double SIL 2 certification of France BV and Shanghai SITIIAS.

● Provide 4-20 mA and with HART, 475 Field Communicator for on-site configuration, calibration and diagnosis.

● Comprehensive fault diagnosis, warning and status history.

● PED pressure vessel certification that meets the requirements of the European Union, and the applicable pressure can reach up to 42MPa.

● The maximum process temperature that can be applied in non-steam applications can reach 500°C.

● CSA, ATEX and IEC explosion-proof, intrinsically safe certification.

● Process parameters can be adjusted online.

● The meter head of the transmitter can be switched freely in 8 directions without affecting the on-site process.

● Suitable for interface measurement and density detection.

● (EMC) EU Electromagnetic Compatibility Directive CE certification.

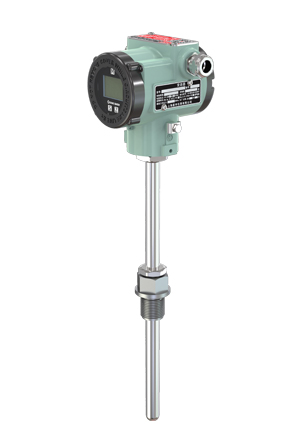

● LG series flow measurement throttling device (orifice plate)

LG series orifice flowmeter is a differential pressure generating device for measuring flow. It can be used with various differential pressure gauges or differential pressure transmitters to measure the flow of various fluids in pipelines. It has the advantages of simple structure, convenient installation, stable performance and high accuracy, and can be used for flow measurement of liquid, steam and gas in modern industry. The throttling device of the orifice flowmeter is used in conjunction with the differential pressure transmitter to measure the flow of liquid, steam, and gas. It is widely used in petroleum, chemical, metallurgy, electric power, light industry and other departments.

Features:

● The structure is easy to replicate, simple and solid, with stable and reliable performance, long service life and low price.

● Orifice plate calculation adopts international standards and processing.

● The orifice flowmeter has a wide range of applications. It can measure all single-phase flows and some mixed-phase flows.

● The standard throttling device can be put into use without actual flow calibration.

● Imported monocrystalline silicon intelligent differential pressure sensor.

● High precision, complete self-diagnosis function.

● Intelligent orifice flowmeter The measuring range of the intelligent orifice flowmeter can be adjusted by programming.

● The smart orifice flowmeter can simultaneously display cumulative flow, instantaneous flow, pressure and temperature.

● In addition to the online and dynamic full compensation function, the intelligent orifice flowmeter also has self-diagnosis and self-setting range.

● Equipped with various communication interfaces.

● High stability.

● Wide measuring range, greater than 10:1.

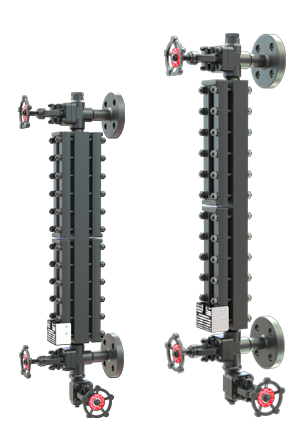

● UGS color quartz glass tube liquid level gauge

UGS series colored quartz glass liquid level gauge is a product manufactured by our company using high-purity quartz tube (99.99% SiCh). The instrument has clear display, good sealing performance, high temperature resistance, high pressure, anti-stickiness, long service life, convenient washing and maintenance, and is widely used for liquid level detection and indication of various containers and boilers in petroleum, chemical, electric power, metallurgy and other industries, especially It is suitable for the measurement indication of colorless and transparent liquids (such as water, liquid chlorine, light oil, liquefied petroleum gas, propylene, etc.).

Features:

● Visual display, easy to clean.

● All stainless steel shell, novel and beautiful.

● Simple structure, loop flange connection.

● Good sealing performance, reliable operation, convenient installation and maintenance.

● The glass tube is made of borosilicate glass or quartz glass tube resistant to harsh environments, which is resistant to temperature, pressure and corrosion.

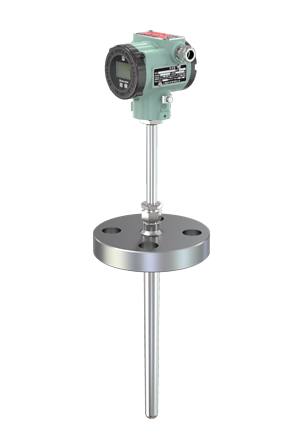

● LGY700 integrated orifice flowmeter

The integrated orifice flowmeter uses standard or non-standard throttling devices to generate differential pressure signals, and detects differential pressure and fluid pressure and temperature signals through differential pressure, pressure and temperature sensors, and then through conversion electrical appliances and CPU processing, the influence on the Various factors of measurement accuracy are dynamically fully compensated on-line, and the flow rate of the fluid can be accurately measured, and various media such as liquid, gas, and steam can be measured. Among them, the throttling device implements the standard of GB/T2624-93 “Measurement of Fluid Flow Filled with Round Pipe by Orifice Plate, Nozzle and Venturi Tube for Flow Measurement Throttling Device”.

Features:

● LGY700 integrated orifice flowmeter has compact structure, simple installation, and can save a lot of installation work time.

● All products are assembled in the factory to ensure stable and consistent measurement accuracy.

●Imported differential pressure transmitter is adopted, and the throttling device implements the national standard, and the actual measurement accuracy is determined through the inspection of the flow standard device.

● Equipped with temperature and pressure compensation algorithm, which improves the measurement accuracy of actual working conditions.

● UHZ-517F60 large and medium-sized storage tank high viscosity inner float magnetic flap liquid level gauge

The magnetic flap liquid level gauge is an all-steel structure on-site indicating instrument, which is mainly composed of main pipe, liquid level indicator, magnetic floating ball, guiding mechanism and other components. The liquid level gauge is designed and manufactured according to Archimedes’ law and the principle of magnetic coupling. The magnetic float is placed in the non-magnetic main pipe. Through the buoyancy of the medium in the main pipe, the float moves up and down with the liquid level of the medium, and then through the principle of magnetic coupling, it drives the liquid level indicator outside the main pipe to rise and fall synchronously to indicate the liquid. s position.

Features:

● The buoy level gauge has a beautiful appearance, strong structure, clear indication and convenient observation.

● All products are assembled in the factory to ensure stable and consistent measurement accuracy.

● Suitable for liquid level measurement of large storage tanks in petrochemical systems, especially for liquid level detection of heavy oil, tar, crude oil, resin and other high-viscosity media

● If the remote transmitter and control switch produced by our company are selected, the remote liquid level indication, detection, recording, control and alarm can be realized conveniently.

中文

中文