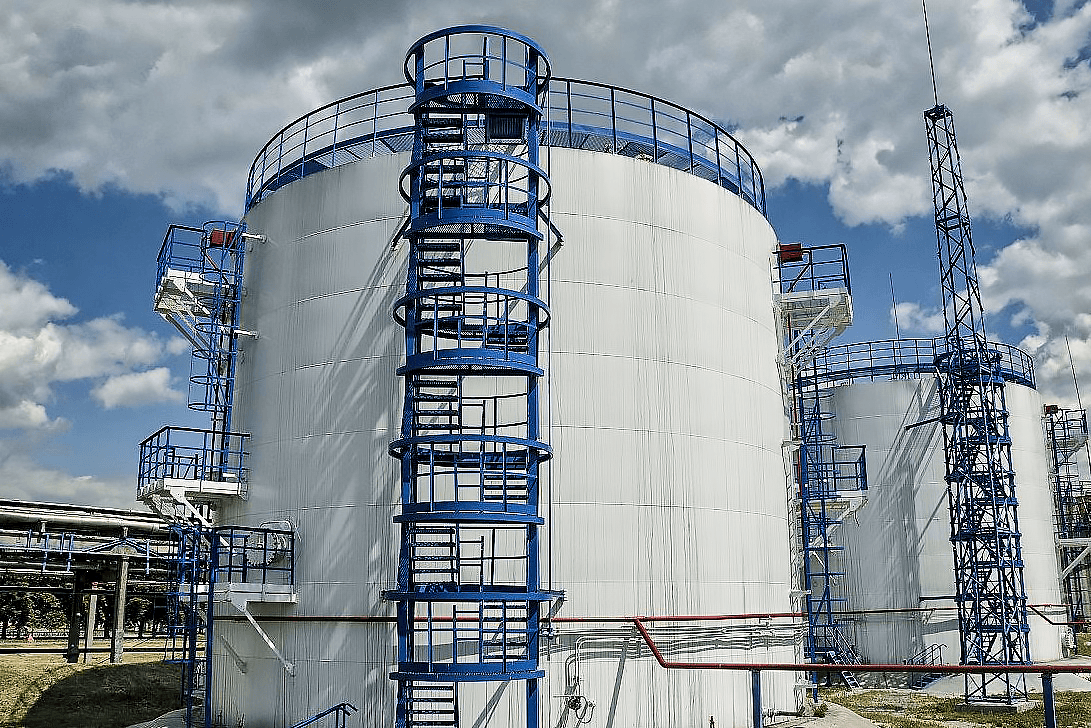

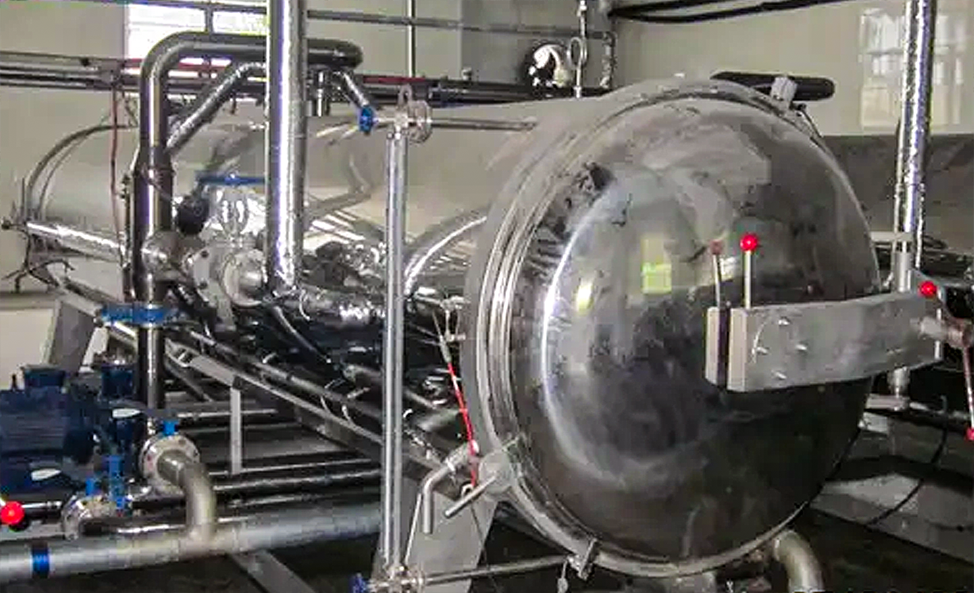

Vaporized ammonia is used for emission control in catalytic and non-catalytic reduction systems. Liquid ammonia is injected into the flue gas stream to act as a reducing agent. It is also used to increase the efficiency of dust collectors in controlling particulate matter. Pure ammonia is stored in a pressure vessel rated at 250 to 300 psig. Ammonia (70% to 80% water) is stored in a tank rated at 25 to 30 psig. The storage capacity of aqueous ammonia is three to four times that of pure ammonia.

Challenge:

Accidental release of pure ammonia gas into the atmosphere is harmful, so safety and environmental measures need to be considered when selecting a liquid level control solution.

Product:

● RF2000Series guided wave radar level meter

The manufacturing technology of RF2000 series guided wave radar level gauges all come from our company. After years of demonstration by radar liquid level experts, the quality and quality are guaranteed in all aspects; RF2000 series guided wave radar level gauges have various forms and installation methods, which are almost suitable for The measurement of the entire liquid (interface) surface can also be applied to the measurement of dust, flour, sand and granular materials, which can completely replace the use of buoys and magnetic liquid level gauges; it has many advantages, such as during the measurement process, Its measurement accuracy is not affected by changes in medium density, temperature, pressure, etc.; it also has simple installation and debugging methods, and it can be used only by inputting configuration data. It is a relatively advanced liquid level instrument and is widely used in petroleum , chemical industry, electric power, metallurgy, pharmaceutical, food, oil and grain storage and other industries.

Features:

● Two-wire DC 24V power supply with low power consumption and HART communication protocol.

● Transmitter head has good compatibility and high stability.

● The performance is not affected by the change of technological conditions such as the specific gravity of the medium, the dielectric constant, and the temperature within the specified range.

● The coaxial antenna (probe) assembly has a unique sealing form, no leakage, high pressure resistance, not easy to aging, and long life.

● The double-rod probe will not affect the correct measurement when part of the material hangs on it, and has high measurement accuracy.

● RF2000 series transmitters can measure medium with extremely low dielectric constant which cannot be measured by traditional guided wave radar.

● RF2000 series transmitters are suitable for medium liquid level measurement under high temperature and high pressure working conditions.

● The length of rod type probe rod can reach 0.5~6m, and the length of cable type probe rod can reach 21m

● The transmitter part (meter head) is interchangeable, and the maintenance is more convenient.

● The zero position and range can be adjusted locally, or remotely adjusted through a remote handheld operator, desktop or portable computer.

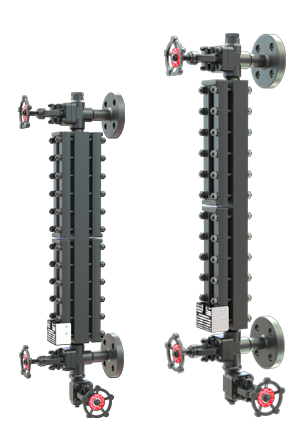

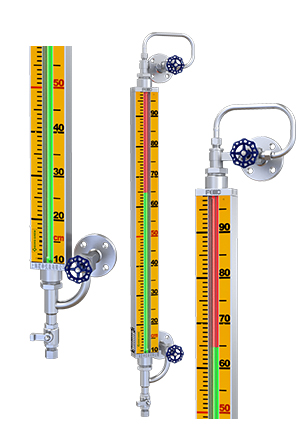

● UHZ-517series magnetic flap liquid level gauge

UHZ-517 series magnetic flap liquid level gauge is a new type of on-site display instrument. The product has the characteristics of simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safety and reliability, and convenient installation, use and maintenance. This product is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, pharmaceutical, papermaking, environmental protection and other industries to provide on-site indication of the liquid level in various storage tanks, tanks and other containers, and the company’s production All kinds of liquid level transmitters and liquid level switches realize the automatic process control and measurement of various industries.

Features:

● Simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safe and reliable, easy to install, use and maintain.

● The float is made of 304, 316 (L), 321, PP, PVC, PTFE and F46 materials, and the float has good high temperature resistance, which can reach 520°C.

● The welding process meets the requirements of PED welding process. The outer cylinder is made of 304 and 316L materials, and the maximum pressure resistance can reach 25Mpa.

● Optional local indication type, remote transmission type, and liquid level alarm type.

● According to the needs of customers, through various types of production, it can be applied to various working conditions.

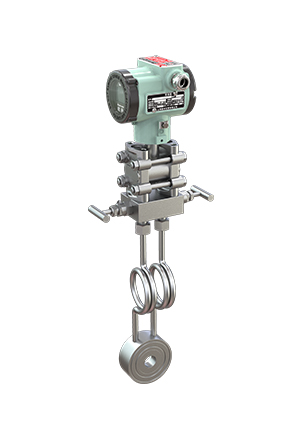

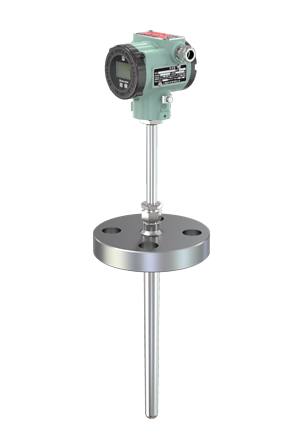

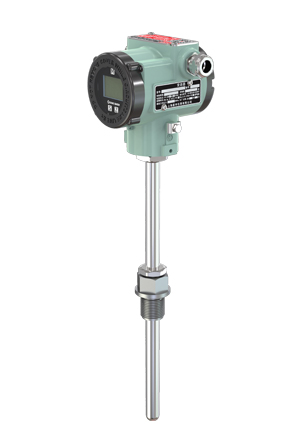

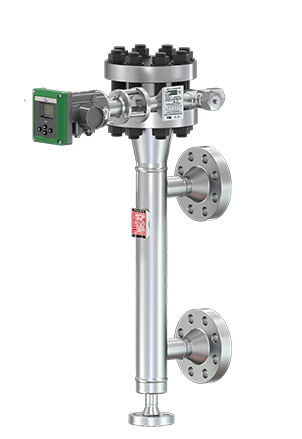

● LCseries intelligent displacer liquid (interface) level transmitter

LC series displacer type liquid level gauge is designed according to the principle of Archimedes buoyancy, and is used to measure liquid level, interface and density of liquid. It has high measurement stability, especially suitable for liquid level/interface measurement occasions with small range, high temperature, high pressure, and low density, and can meet the interface measurement with small medium density difference. The transmitter can conveniently perform remote configuration and management (monitoring) of the transmitter through the HART communication protocol, using a PC or a general-purpose handheld terminal, and can also be operated with conventional local keys.

Features:

● Double SIL 2 certification of France BV and Shanghai SITIIAS.

● Provide 4-20 mA and with HART, 475 Field Communicator for on-site configuration, calibration and diagnosis.

● Comprehensive fault diagnosis, warning and status history.

● PED pressure vessel certification that meets the requirements of the European Union, and the applicable pressure can reach up to 42MPa.

● The maximum process temperature that can be applied in non-steam applications can reach 500°C.

● CSA, ATEX and IEC explosion-proof, intrinsically safe certification.

● Process parameters can be adjusted online.

● The meter head of the transmitter can be switched freely in 8 directions without affecting the on-site process.

● Suitable for interface measurement and density detection.

● (EMC) EU Electromagnetic Compatibility Directive CE certification.

中文

中文