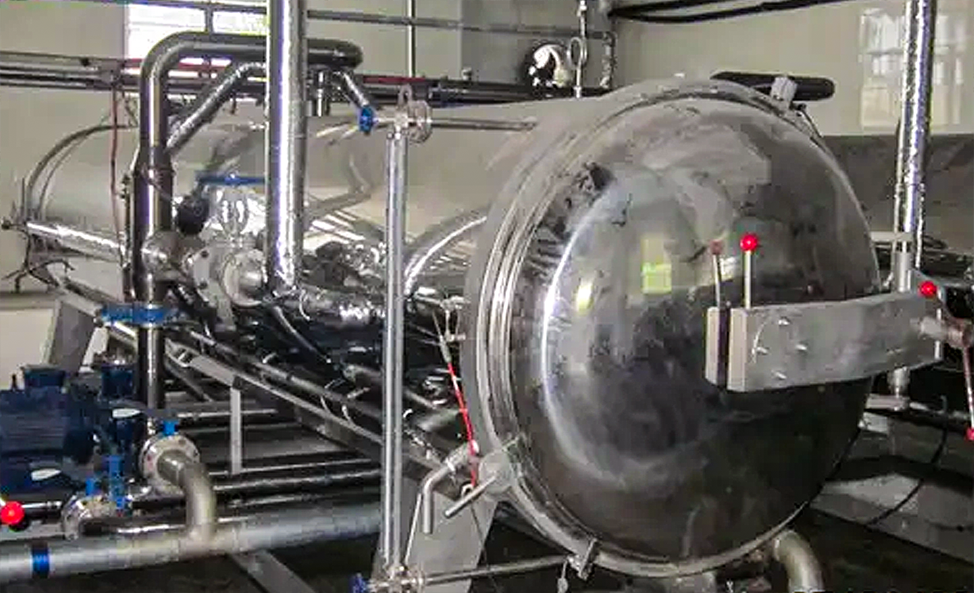

Heavier feedstocks are generally difficult to process by catalytic cracking or reforming, but can be converted by hydrocracking. The feedstock is cracked by catalytic cracking in the presence of hydrogen, and hydrocracking produces a mixed stream of gasoline and distillates. About a dozen different hydrocracking process schemes are currently in use.

challenge:

Catalyst stripper, separator liquid and flash tank liquid level control must be adapted to harsh process conditions to maintain optimal operation of the hydrocracker. These conditions include elevated temperature and pressure, the presence of steam and high-pressure hydrogen, and corrosive liquids.

product:

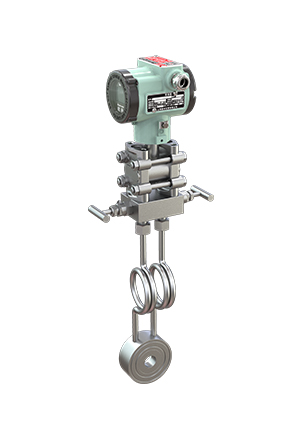

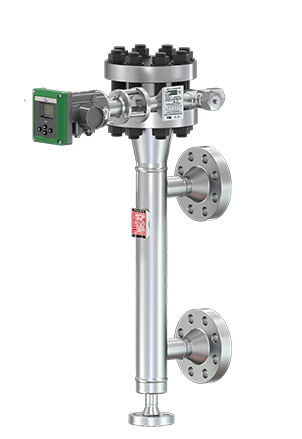

● LC series intelligent displacer liquid (interface) level transmitter

LC series displacer type liquid level gauge is designed according to the principle of Archimedes buoyancy, and is used to measure liquid level, interface and density of liquid. It has high measurement stability, especially suitable for liquid level/interface measurement occasions with small range, high temperature, high pressure, and low density, and can meet the interface measurement with small medium density difference. The transmitter can conveniently perform remote configuration and management (monitoring) of the transmitter through the HART communication protocol, using a PC or a general-purpose handheld terminal, and can also be operated with conventional local keys.

Features:

● Double SIL 2 certification of France BV and Shanghai SITIIAS.

● Provide 4-20 mA and with HART, 475 Field Communicator for on-site configuration, calibration and diagnosis.

● Comprehensive fault diagnosis, warning and status history.

● PED pressure vessel certification that meets the requirements of the European Union, and the applicable pressure can reach up to 42MPa.

● The maximum process temperature that can be applied in non-steam applications can reach 500°C.

● CSA, ATEX and IEC explosion-proof, intrinsically safe certification.

● Process parameters can be adjusted online.

● The meter head of the transmitter can be switched freely in 8 directions without affecting the on-site process.

● Suitable for interface measurement and density detection.

● (EMC) EU Electromagnetic Compatibility Directive CE certification.

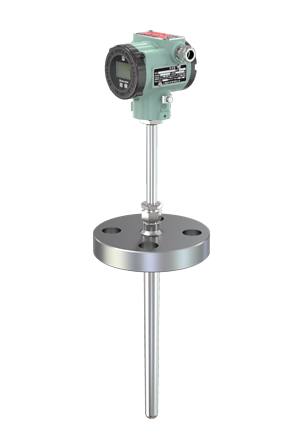

● RF2000 Guided Wave Radar Level Meter

The manufacturing technology of RF2000 series guided wave radar level gauges all come from our company. After years of demonstration by radar liquid level experts, the quality and quality are guaranteed in all aspects; RF2000 series guided wave radar level gauges have various forms and installation methods, which are almost suitable for The measurement of the entire liquid (interface) surface can also be applied to the measurement of dust, flour, sand and granular materials, which can completely replace the use of buoys and magnetic liquid level gauges; it has many advantages, such as during the measurement process, Its measurement accuracy is not affected by changes in medium density, temperature, pressure, etc.; it also has simple installation and debugging methods, and it can be used only by inputting configuration data. It is a relatively advanced liquid level instrument and is widely used in petroleum , chemical industry, electric power, metallurgy, pharmaceutical, food, oil and grain storage and other industries.

Features:

● Two-wire DC 24V power supply with low power consumption and HART communication protocol.

● Transmitter head has good compatibility and high stability.

● The performance is not affected by the change of technological conditions such as the specific gravity of the medium, the dielectric constant, and the temperature within the specified range.

● The coaxial antenna (probe) assembly has a unique sealing form, no leakage, high pressure resistance, not easy to aging, and long life.

● The double-rod probe will not affect the correct measurement when part of the material hangs on it, and has high measurement accuracy.

● RF2000 series transmitters can measure medium with extremely low dielectric constant which cannot be measured by traditional guided wave radar.

● RF2000 series transmitters are suitable for medium liquid level measurement under high temperature and high pressure working conditions.

● The length of rod type probe rod can reach 0.5~6m, and the length of cable type probe rod can reach 21m

● The transmitter part (meter head) is interchangeable, and the maintenance is more convenient.

● The zero position and range can be adjusted locally, or remotely adjusted through a remote handheld operator, desktop or portable computer.

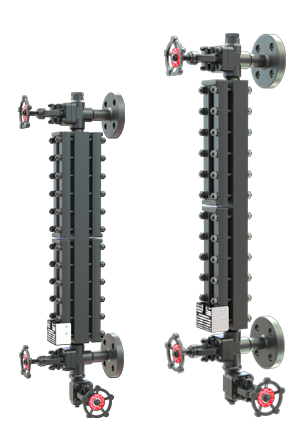

● UHZ-517 series magnetic flap liquid level gauge

UHZ-517 series magnetic flap liquid level gauge is a new type of on-site display instrument. The product has the characteristics of simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safety and reliability, and convenient installation, use and maintenance. This product is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, pharmaceutical, papermaking, environmental protection and other industries to provide on-site indication of the liquid level in various storage tanks, tanks and other containers, and the company’s production All kinds of liquid level transmitters and liquid level switches realize the automatic process control and measurement of various industries.

Features:

● Simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safe and reliable, easy to install, use and maintain.

● The float is made of 304, 316 (L), 321, PP, PVC, PTFE and F46 materials, and the float has good high temperature resistance, which can reach 520°C.

● The welding process meets the requirements of PED welding process. The outer cylinder is made of 304 and 316L materials, and the maximum pressure resistance can reach 25Mpa.

● Optional local indication type, remote transmission type, and liquid level alarm type.

● According to the needs of customers, through various types of production, it can be applied to various working conditions.

● UQK6 series float (float) liquid level switch

UQK-6000/6100 series float liquid level switch and UQK-6200 series float liquid level switch are designed and manufactured according to high temperature and high pressure applications. The products refer to ANSIB31.1 standard design, adopt advanced three-magnet mechanism switch, reasonable and reliable structure High performance, can accurately identify the liquid level under harsh working conditions, and perform switching actions. It is suitable for the control, alarm and fault interlock of various high-temperature, high-pressure and open container liquid levels in the production process of petroleum, chemical, electric power, food, pharmaceutical and other industries.

When UQK series products are designed and manufactured, they fully consider the different forms of process connection in the imported equipment in the petrochemical industry, and design a variety of installation methods with various structures. It is an ideal substitute for similar switches in Europe and America.

Features:

● Unique “three magnets” mechanism, no spring, no cam, no friction surface.

● Explosion-proof and sealed structure, alumina ceramic switch body.

● Suitable for high temperature, high pressure, low temperature, ultra-low temperature, shockproof occasions.

● ANSI B31.1 standard design.

● 316L guide rod, high temperature resistant permanent rare earth magnet.

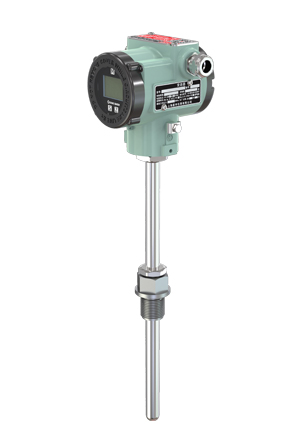

● LG series flow measurement throttling device (orifice plate)

LG series orifice flowmeter is a differential pressure generating device for measuring flow. It can be used with various differential pressure gauges or differential pressure transmitters to measure the flow of various fluids in pipelines. It has the advantages of simple structure, convenient installation, stable performance and high accuracy, and can be used for flow measurement of liquid, steam and gas in modern industry. The throttling device of the orifice flowmeter is used in conjunction with the differential pressure transmitter to measure the flow of liquid, steam, and gas. It is widely used in petroleum, chemical, metallurgy, electric power, light industry and other departments.

Features:

● The structure is easy to replicate, simple and solid, with stable and reliable performance, long service life and low price.

● Orifice plate calculation adopts international standards and processing.

● The orifice flowmeter has a wide range of applications. It can measure all single-phase flows and some mixed-phase flows.

● The standard throttling device can be put into use without actual flow calibration.

● Imported monocrystalline silicon intelligent differential pressure sensor.

● High precision, complete self-diagnosis function.

● Intelligent orifice flowmeter The measuring range of the intelligent orifice flowmeter can be adjusted by programming.

● The smart orifice flowmeter can simultaneously display cumulative flow, instantaneous flow, pressure and temperature.

● In addition to the online and dynamic full compensation function, the intelligent orifice flowmeter also has self-diagnosis and self-setting range.

● Equipped with various communication interfaces.

● High stability.

● Wide measuring range, greater than 10:1.

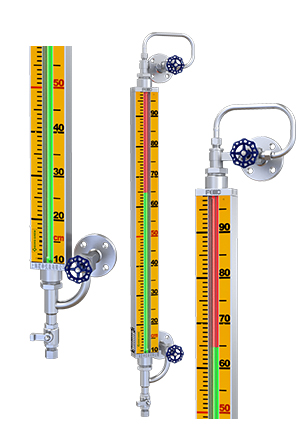

● UB series glass plate liquid level gauge

UB series ordinary, high temperature, high pressure, low temperature anti-frost, large diameter glass plate liquid level gauge can be directly used to indicate the liquid level of various industrial containers. The heat-treated borosilicate glass is used below the working temperature of 260C, and the special heat-treated aluminosilicate glass is used above 260C, which can withstand the medium temperature of 420C.

Features:

● Safety steel balls are installed on the glass plate level gauges. If the glass plate level gauges are accidentally broken, the steel balls will seal the valve port under the action of pressure difference and block the passage of medium flowing into the glass plate level gauges.

● Suzuki glass plate liquid level gauge can realize the measurement of high temperature, high pressure and high temperature and high pressure working conditions.

● When the medium is steam, lye, or medium with pH>7, mica pads are added between the glass plate and the sealing gasket to protect the glass plate from being corroded by the medium.

● UGS color quartz glass tube liquid level gauge

UGS series colored quartz glass liquid level gauge is a product manufactured by our company using high-purity quartz tube (99.99% SiCh). The instrument has clear display, good sealing performance, high temperature resistance, high pressure, anti-stickiness, long service life, convenient washing and maintenance, and is widely used for liquid level detection and indication of various containers and boilers in petroleum, chemical, electric power, metallurgy and other industries, especially It is suitable for the measurement indication of colorless and transparent liquids (such as water, liquid chlorine, light oil, liquefied petroleum gas, propylene, etc.).

Features:

● Visual display, easy to clean.

● All stainless steel shell, novel and beautiful.

● Simple structure, loop flange connection.

● Good sealing performance, reliable operation, convenient installation and maintenance.

● The glass tube is made of borosilicate glass or quartz glass tube resistant to harsh environments, which is resistant to temperature, pressure and corrosion.

● LGY700 integrated orifice flowmeter

The integrated orifice flowmeter uses standard or non-standard throttling devices to generate differential pressure signals, and detects differential pressure and fluid pressure and temperature signals through differential pressure, pressure and temperature sensors, and then through conversion electrical appliances and CPU processing, the influence on the Various factors of measurement accuracy are dynamically fully compensated on-line, and the flow rate of the fluid can be accurately measured, and various media such as liquid, gas, and steam can be measured. Among them, the throttling device implements the standard of GB/T2624-93 “Measurement of Fluid Flow Filled with Round Pipe by Orifice Plate, Nozzle and Venturi Tube for Flow Measurement Throttling Device”.

Features:

● LGY700 integrated orifice flowmeter has compact structure, simple installation, and can save a lot of installation work time.

● All products are assembled in the factory to ensure stable and consistent measurement accuracy.

●Imported differential pressure transmitter is adopted, and the throttling device implements the national standard, and the actual measurement accuracy is determined through the inspection of the flow standard device.

● Equipped with temperature and pressure compensation algorithm, which improves the measurement accuracy of actual working conditions.

中文

中文