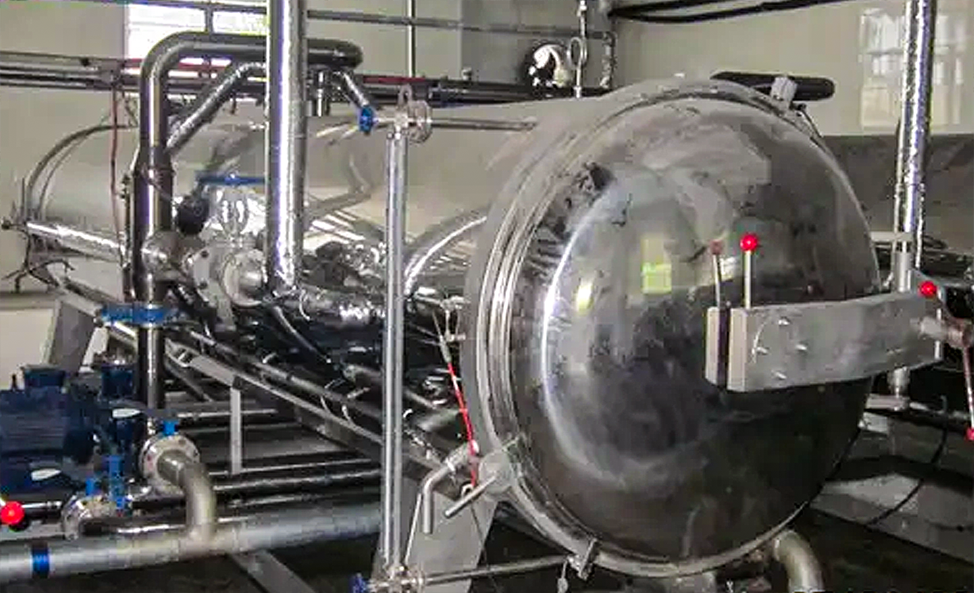

Coking is the final means of converting the heaviest products of atmospheric and vacuum distillation. The feed is heated and cracked into light gases, gasoline blendstocks, distillates and diesel. Level applications for delayed and continuous (contact or fluid) coking include fractionation columns, gas oil strippers, steam, condensate, blowdown and settling drums, and vent knockout drums.

challenge:

High temperatures, high pressures, foam and steam are serious challenges for liquid level instruments. Installing interface level gauges in vessels prone to foaming helps avoid foam carryover and increases coke drum production.

product:

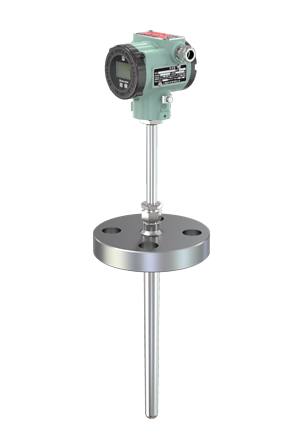

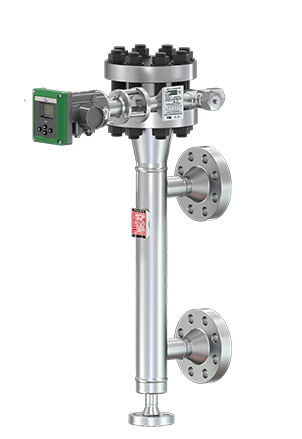

● RF2000 series guided wave radar level meter

The manufacturing technology of RF2000 series guided wave radar level gauges all come from our company. After years of demonstration by radar liquid level experts, the quality and quality are guaranteed in all aspects; RF2000 series guided wave radar level gauges have various forms and installation methods, which are almost suitable for The measurement of the entire liquid (interface) surface can also be applied to the measurement of dust, flour, sand and granular materials, which can completely replace the use of buoys and magnetic liquid level gauges; it has many advantages, such as during the measurement process, Its measurement accuracy is not affected by changes in medium density, temperature, pressure, etc.; it also has simple installation and debugging methods, and it can be used only by inputting configuration data. It is a relatively advanced liquid level instrument and is widely used in petroleum , chemical industry, electric power, metallurgy, pharmaceutical, food, oil and grain storage and other industries.

Features:

● Two-wire DC 24V power supply with low power consumption and HART communication protocol.

● Transmitter head has good compatibility and high stability.

● The performance is not affected by the change of technological conditions such as the specific gravity of the medium, the dielectric constant, and the temperature within the specified range.

● The coaxial antenna (probe) assembly has a unique sealing form, no leakage, high pressure resistance, not easy to aging, and long life.

● The double-rod probe will not affect the correct measurement when part of the material hangs on it, and has high measurement accuracy.

● RF2000 series transmitters can measure medium with extremely low dielectric constant which cannot be measured by traditional guided wave radar.

● RF2000 series transmitters are suitable for medium liquid level measurement under high temperature and high pressure working conditions.

● Rod probe length can reach 0.5~6m, and cable probe can reach 21m.

● The transmitter part (meter head) is interchangeable, and the maintenance is more convenient.

● The zero position and range can be adjusted locally, or remotely adjusted through a remote handheld operator, desktop or portable computer.

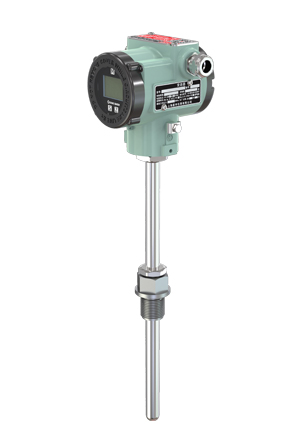

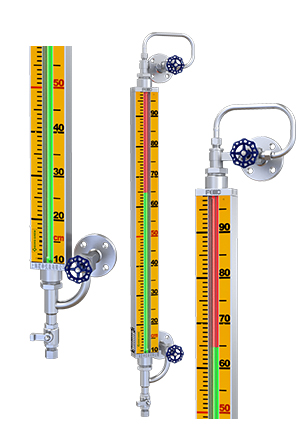

● UHZ-517 series magnetic flap liquid level gauge

UHZ-517 series magnetic flap liquid level gauge is a new type of on-site display instrument. The product has the characteristics of simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safety and reliability, and convenient installation, use and maintenance. This product is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, pharmaceutical, papermaking, environmental protection and other industries to provide on-site indication of the liquid level in various storage tanks, tanks and other containers, and the company’s production All kinds of liquid level transmitters and liquid level switches realize the automatic process control and measurement of various industries.

Features:

● Simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safe and reliable, easy to install, use and maintain.

● The float is made of 304, 316 (L), 321, PP, PVC, PTFE and F46 materials, and the float has good high temperature resistance, which can reach 520°C.

● The welding process meets the requirements of PED welding process. The outer cylinder is made of 304 and 316L materials, and the maximum pressure resistance can reach 25Mpa.

● Optional local indication type, remote transmission type, and liquid level alarm type.

● According to the needs of customers, through various types of production, it can be applied to various working conditions.

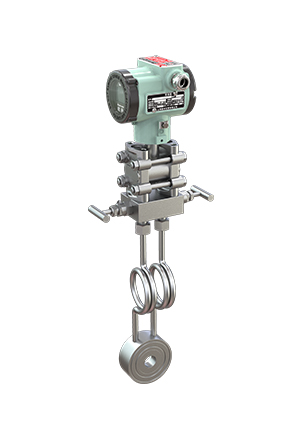

● LG series flow measurement throttling device (orifice plate)

LG series orifice flowmeter is a differential pressure generating device for measuring flow. It can be used with various differential pressure gauges or differential pressure transmitters to measure the flow of various fluids in pipelines. It has the advantages of simple structure, convenient installation, stable performance and high accuracy, and can be used for flow measurement of liquid, steam and gas in modern industry. The throttling device of the orifice flowmeter is used in conjunction with the differential pressure transmitter to measure the flow of liquid, steam, and gas. It is widely used in petroleum, chemical, metallurgy, electric power, light industry and other departments.

Features:

● The structure is easy to replicate, simple and firm, with stable and reliable performance, long service life and low price.

● Orifice plate calculation adopts international standards and processing.

● The orifice flowmeter has a wide range of applications. It can measure all single-phase flows and some mixed-phase flows.

● The standard throttling device can be put into use without actual flow calibration.

● Imported monocrystalline silicon intelligent differential pressure sensor.

● High precision, complete self-diagnosis function.

● Intelligent orifice flowmeter The measuring range of the intelligent orifice flowmeter can be adjusted by programming.

● The smart orifice flowmeter can simultaneously display cumulative flow, instantaneous flow, pressure and temperature.

● In addition to the online and dynamic full compensation function, the intelligent orifice flowmeter also has self-diagnosis and self-setting range.

● Equipped with various communication interfaces.

● High stability.

● Wide measuring range, greater than 10:1.

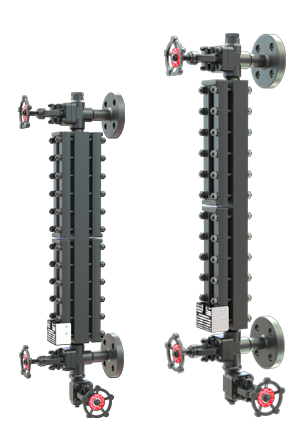

● UHZ-517F60 large and medium-sized storage tank high viscosity inner float magnetic flap liquid level gauge

The magnetic flap liquid level gauge is an all-steel structure on-site indicating instrument, which is mainly composed of main pipe, liquid level indicator, magnetic floating ball, guiding mechanism and other components. The liquid level gauge is designed and manufactured according to Archimedes’ law and the principle of magnetic coupling. The magnetic float is placed in the non-magnetic main pipe. Through the buoyancy of the medium in the main pipe, the float moves up and down with the liquid level of the medium, and then through the principle of magnetic coupling, it drives the liquid level indicator outside the main pipe to rise and fall synchronously to indicate the liquid. s position.

Features:

● The buoy level gauge has a beautiful appearance, strong structure, clear indication and convenient observation.

● All products are assembled in the factory to ensure stable and consistent measurement accuracy.

● Suitable for liquid level measurement of large storage tanks in petrochemical systems, especially for liquid level detection of heavy oil, tar, crude oil, resin and other high-viscosity media

● If the remote transmitter and control switch produced by our company are selected, the remote liquid level indication, detection, recording, control and alarm can be realized conveniently.

中文

中文