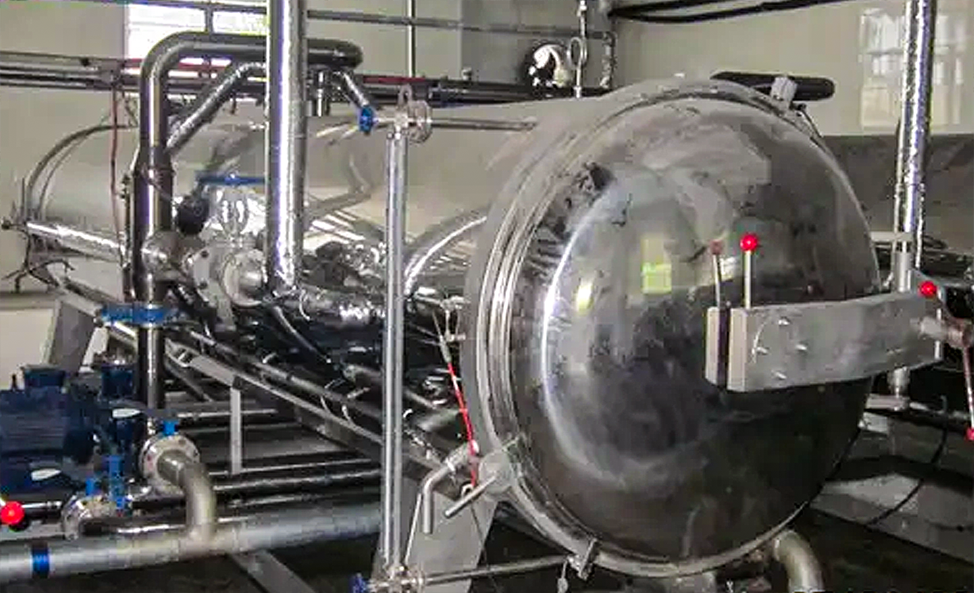

From Active Pharmaceutical Ingredients (APIs) to Vapor Phase Corrosion Inhibitors (VCIs), 1000s of additives and any reagent can be injected into an industry-specific process stream to alter or impart new product characteristics or enhance processing dynamics. Injection systems and chemical skid systems offer a variety of different dosage control options. The whole process requires liquid level detection and flow monitoring of injected chemical reagents.

Challenge:

A chemical injection system typically consists of one or more chemical supply tanks or drums, a metering tank, a vessel with agitator (if required), a variable displacement pump and process controller. Chemical tanks and chemical skids require level monitoring to ensure these tanks do not overflow or run out of chemicals.

Products:

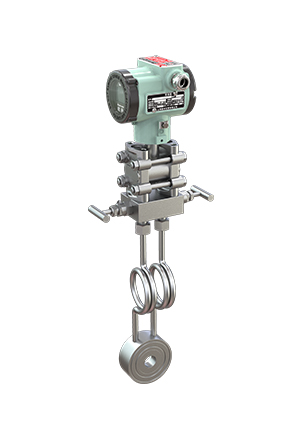

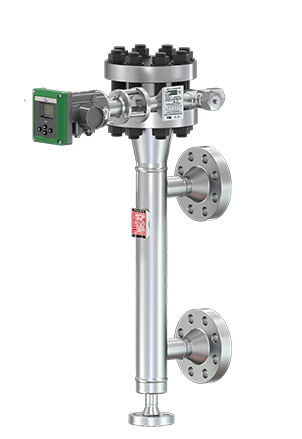

● RF2000 Series Guided Wave Radar Level Meter

The manufacturing technology of RF2000 series guided wave radar level gauges all come from our company. After years of demonstration by radar liquid level experts, the quality and quality are guaranteed in all aspects; RF2000 series guided wave radar level gauges have various forms and installation methods, which are almost suitable for The measurement of the entire liquid (interface) surface can also be applied to the measurement of dust, flour, sand and granular materials, which can completely replace the use of buoys and magnetic liquid level gauges; it has many advantages, such as during the measurement process, Its measurement accuracy is not affected by changes in medium density, temperature, pressure, etc.; it also has simple installation and debugging methods, and it can be used only by inputting configuration data. It is a relatively advanced liquid level instrument and is widely used in petroleum , chemical industry, electric power, metallurgy, pharmaceutical, food, oil and grain storage and other industries.

Features:

● Two-wire DC 24V power supply with low power consumption and HART communication protocol.

● The performance will not be affected by the change of process conditions such as the specific gravity, dielectric constant and temperature of the medium within the specified range.

● The coaxial antenna (probe) assembly has a unique sealing form, no leakage, high pressure resistance, not easy to aging, and long life.

● The double-rod probe will not affect the correct measurement when part of the material hangs on it, and has high measurement accuracy.

● It can measure the medium with extremely low dielectric constant which cannot be measured by traditional guided wave radar.

● RF2000 series transmitters are suitable for medium liquid level measurement under high temperature and high pressure working conditions.

● The length of the rod type probe rod can reach 0.5~6m, and the length of the cable type probe rod can reach 21m

● The transmitter part (meter head) is interchangeable, more convenient for maintenance, good compatibility and high stability.

● The zero position and range can be adjusted on site, and can also be adjusted remotely through a remote handheld operator, desktop, or portable computer.

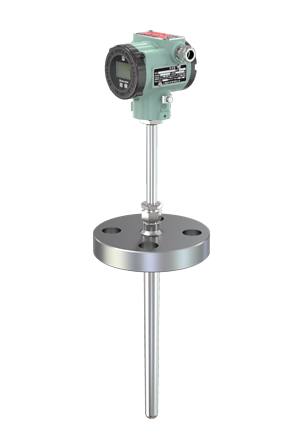

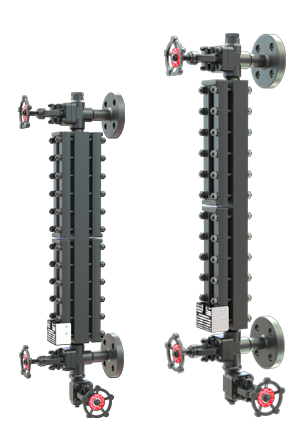

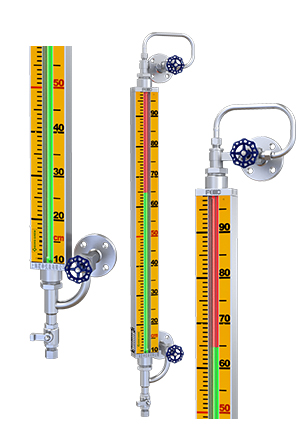

● UHZ-517 Series Magnetic Flap Level Gauge

UHZ-517 series magnetic flap liquid level gauge is a new type of on-site display instrument. The product has the characteristics of simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safety and reliability, and convenient installation, use and maintenance. This product is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, pharmaceutical, papermaking, environmental protection and other industries to provide on-site indication of the liquid level in various storage tanks, tanks and other containers, and the company’s production All kinds of liquid level transmitters and liquid level switches realize the automatic process control and measurement of various industries.

Features:

● Simple structure, intuitive and novel readings, no blind spot in observation, large measurement range, safe and reliable, easy to install, use and maintain.

● The float is made of 304, 316L, TA2 and TC4 materials, and the float has good high temperature resistance, up to 450°C.

● The welding process meets the requirements of PED welding process. The outer cylinder is made of 304 and 316L materials, and the maximum pressure resistance can reach 26Mpa.

● Optional local indication type, remote transmission type, and liquid level alarm type.

● According to customer needs, through various types of production, it can be applied to various working conditions.

● XSC Series Ultrasonic Flowmeter

XSC series ultrasonic flowmeter is a brand-new universal time-difference multifunctional ultrasonic flowmeter designed by adopting low-voltage multi-pulse balanced transmitting and receiving patented technology. Uniform liquid flow and heat. The accuracy of the ultrasonic flowmeter after calibration can reach 0.5 level. It adopts balanced differential transmitting and balanced differential receiving circuits. It has stronger anti-interference performance and adaptability. The optimization makes the production process simple, and the reliability and consistency of the whole machine are excellent.

The ultrasonic flowmeter with a single circuit board structure is designed using the latest components produced by famous international semiconductor manufacturers and the VLSI produced. The number of hardware is small, low-voltage operation, multi-pulse transmission, low power consumption, high reliability, anti-interference, and good applicability. Optimized intelligent signal adaptive processing, the user does not need any circuit adjustment, just as convenient and simple as using a multimeter. Advanced circuit design, device selection, excellent hardware design and Chinese user-friendly software design make the new version of ultrasonic flowmeter the most advanced and well-deserved first-brand product in China.

In terms of design, the XSC series ultrasonic flowmeter adopts the world’s most advanced integrated circuit and microprocessor intelligent control, which realizes the non-adjustment of component parameters in the production process. The production process is simple and reliable, and the product consistency is good. Guarantee Every machine that leaves the factory has reached the best performance and best working condition.

Features:

● Simple structure, easy installation, use and maintenance.

● There are no components inserted into the fluid, no influence on the flow rate, and no pressure loss.

● It can be used for flow measurement of any liquid, especially liquid with high viscosity, strong corrosion, non-conductivity, etc. It can also measure the flow of gas.

● For the flow measurement of large-diameter pipes, the investment will not be increased due to the large pipe diameter.

● The measuring range is relatively wide, up to 5:1.

● Linear between output and flow.

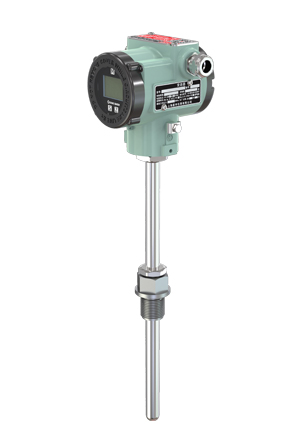

SM2 series vortex flowmeter

SM2 series vortex flowmeter is manufactured by introducing the most advanced international technology. The performance of the product is stable and reliable. It uses the principle of Karman vortex street and the principle of Faraday electromagnetic induction to measure the flow velocity of fluid in a closed pipeline and reflect the flow meter of fluid volume flow. It is composed of a vortex flow sensor and a flow display part, which meets the requirements of the national “JJG1029-2007 Verification Regulations for Vortex Flowmeters”. This series of products can measure saturated steam, superheated steam, general gas, compressed air, natural gas, coal gas, industrial water, drainage, high and low temperature liquid and other media. Widely used in metallurgy, petrochemical, light industry, food, and water treatment industries.

Features:

● Wide range of applications, the flow of steam, gas and liquid can be measured.

● Simple and solid structure, no moving parts, high reliability, very stable long-term operation.

● Wear-resistant, dirt-resistant, no mechanical maintenance, long service life, safe and explosion-proof, suitable for harsh environments.

● Isolated current output, good interference suppression ability.

● Surface mount process circuit, compact structure, high reliability, wide measurement range, range ratio up to 10:1.

● Small pressure loss, wide dynamic measurement range, stainless steel body, strong corrosion resistance.

● (0~5) KHz frequency output, (4~20) mA output or HART communication, Modbus protocol communication, can be connected with industrial automation system.

● On-site liquid crystal display, instantaneous flow display, cumulative total display, percentage display, and frequency display at the same time.

● The three-wire system option supports setting parameters through Bluetooth communication, and can set parameters wirelessly on the instrument within a short distance (within 20 meters), which is convenient for on-site operation.

● Provide temperature and pressure integrated product options to save users’ installation costs.

中文

中文