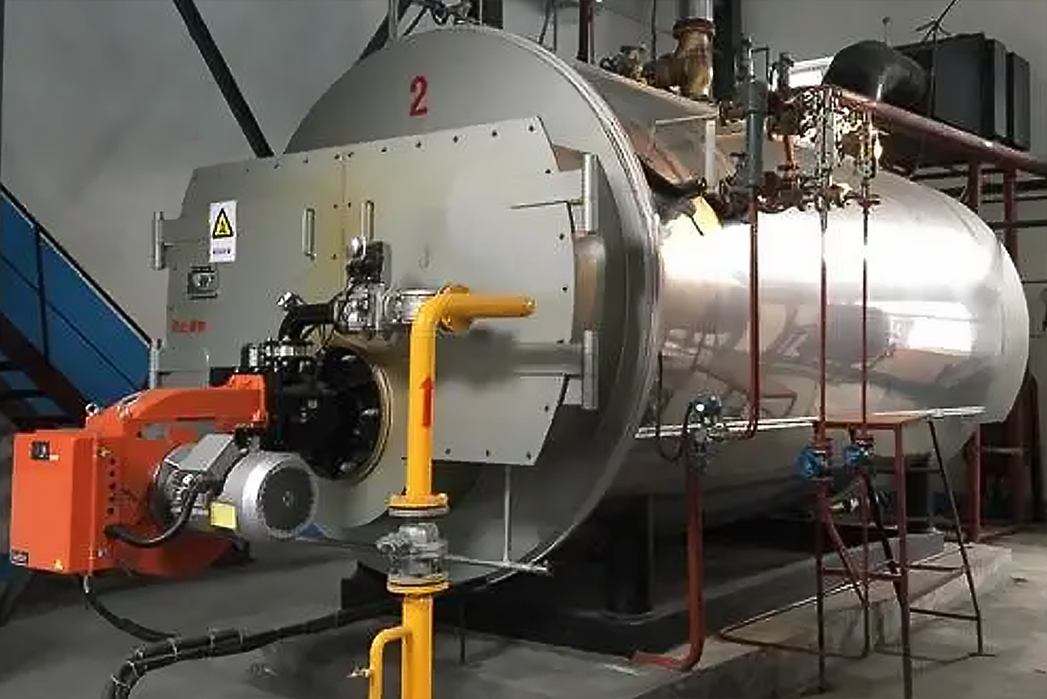

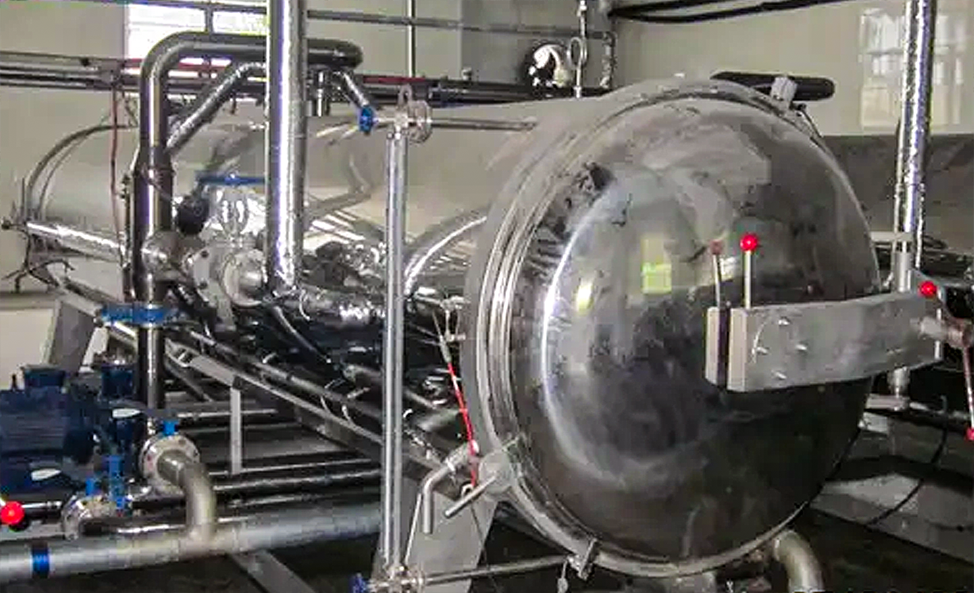

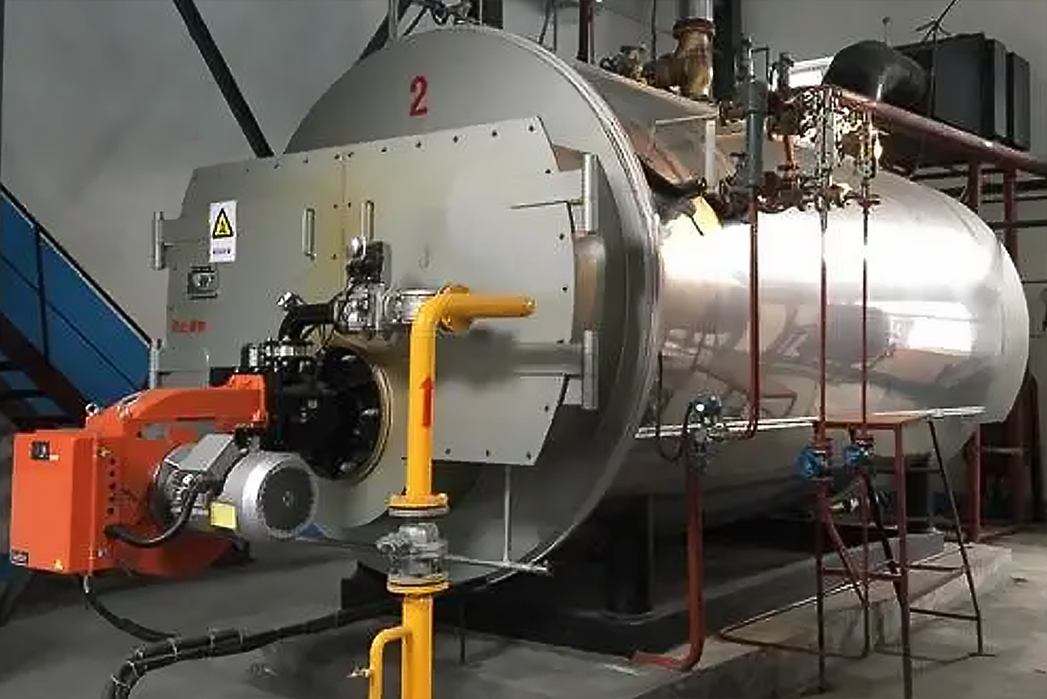

The concentration of undesirable solid particles in boiler water can be reduced by continuous cleaning or blowdown systems. Blowdown tanks receive continuous blowdown from boiler drums and discharges from steam generators at various temperatures and pressures. The blowdown tank also acts as an automatic drain system for the steam generator when draining the generator for maintenance.

Challenge:

Good boiler blowdown practice can greatly reduce a boiler’s water treatment needs and operating costs. However, a flammable mixture can remain in the boiler due to improper cleaning, which can lead to a catastrophic explosion. Therefore, reasonable liquid level control is essential to ensure the safe and effective operation of the boiler blowdown system.

Products:

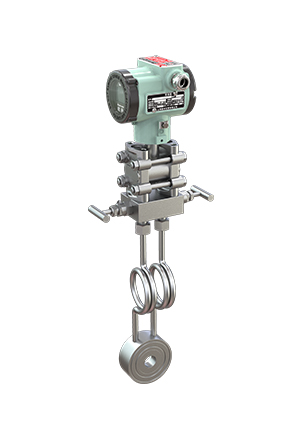

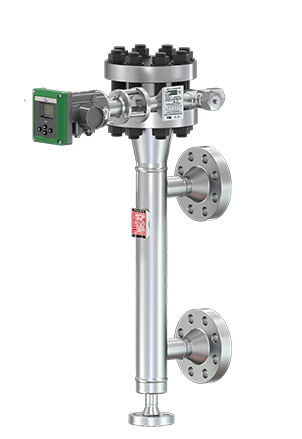

RF2000 Series Guided Wave Radar Level Meter

The manufacturing technology of RF2000 series guided wave radar level gauges all come from our company. After years of demonstration by radar liquid level experts, the quality and quality are guaranteed in all aspects; RF2000 series guided wave radar level gauges have various forms and installation methods, which are almost suitable for The measurement of the entire liquid (interface) surface can also be applied to the measurement of dust, flour, sand and granular materials, which can completely replace the use of buoys and magnetic liquid level gauges; it has many advantages, such as during the measurement process, Its measurement accuracy is not affected by changes in medium density, temperature, pressure, etc.; it also has simple installation and debugging methods, and it can be used only by inputting configuration data. It is a relatively advanced liquid level instrument and is widely used in petroleum , chemical industry, electric power, metallurgy, pharmaceutical, food, oil and grain storage and other industries.

Features:

● Two-wire DC 24V power supply with low power consumption and HART communication protocol.

● The performance will not be affected by the change of process conditions such as the specific gravity, dielectric constant and temperature of the medium within the specified range.

● The coaxial antenna (probe) assembly has a unique sealing form, no leakage, high pressure resistance, not easy to aging, and long life.

● The double-rod probe will not affect the correct measurement when part of the material hangs on it, and has high measurement accuracy.

● It can measure the medium with extremely low dielectric constant which cannot be measured by traditional guided wave radar.

● RF2000 series transmitters are suitable for medium liquid level measurement under high temperature and high pressure working conditions.

● The length of the rod type probe rod can reach 0.5~6m, and the length of the cable type probe rod can reach 21m

● The transmitter part (meter head) is interchangeable, more convenient for maintenance, good compatibility and high stability.

● The zero position and range can be adjusted on site, and can also be adjusted remotely through a remote handheld operator, desktop, or portable computer.

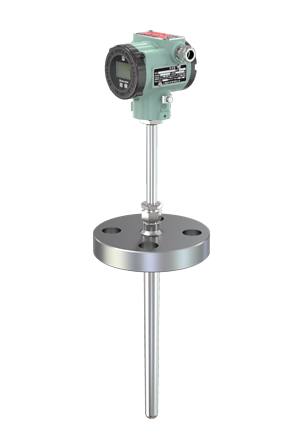

● UQK6 series float (float) liquid level switch

UQK-6000/6100 series float level switches and UQK-6200 series float level switches are designed and manufactured according to high temperature and high pressure applications, and the products refer to ANSIB31.1 standard design , using advanced three-magnet mechanism switch, reasonable structure, high reliability, can accurately identify the liquid level under harsh working conditions, and perform switching actions. It is suitable for the control, alarm and fault interlock of various high-temperature, high-pressure and open container liquid levels in the production process of petroleum, chemical, electric power, food, pharmaceutical and other industries.

When UQK series products are designed and manufactured, they fully consider the different forms of process connection in the imported equipment in the petrochemical industry, and design a variety of installation methods with various structures. It is an ideal substitute for similar switches in Europe and America.

Features:

● Unique “three magnetic” mechanism, no spring, no cam, no friction surface.

● Explosion-proof sealed structure, alumina ceramic switch body.

● Suitable for high temperature, high pressure, low temperature, ultra-low temperature, shockproof occasions.

● ANSI B31.1 standard design.

● 316L guide rod, high temperature resistant permanent rare earth magnet.

● Support multiple operation and configuration methods such as host computer setting software, mobile phone APP, LCD keyboard module, tank side meter, etc.

● 24VDC, 220VAC two power supply models.

● Simple installation structure, suitable for various installation forms on site.

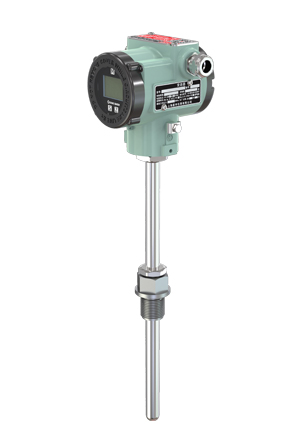

● FS300 tuning fork level switch

FS300 series tuning fork level switch is a new type of level switch. The tuning fork is excited by the crystal to generate vibration. When the tuning fork is immersed in the material, the vibration frequency changes. This frequency change is detected by the electronic circuit and outputs a switch value.

The tuning fork type level switch is also called “electrical float”. Where the float level switch is used and the float level switch cannot be used due to structure, turbulence, agitation, air bubbles, vibration and other reasons, the “fork” can be used. Because the tuning fork level switch has no moving parts, it does not need maintenance and adjustment. It is an upgraded product of the float level switch. Tuning fork level switches are widely used in petrochemical, light industry, food, water treatment and other industries to perform upper/lower limit alarm and control on material level.

Features:

● Strong adaptability: not affected by medium disturbance, electrical parameters, solid gas composition and foam. Scale, agitation, turbulence, air bubbles, vibration, medium viscosity, high temperature, high pressure and other harsh conditions will not affect the detection.

● Free from maintenance: Since the detection process of the tuning fork limit switch is completed by an electronic circuit without moving parts, it is safe and reliable, so it does not require maintenance once it is installed and put into operation.

● No need to adjust: Since the detection of the tuning fork limit switch is not affected by the electrical parameters of the measured medium, no on-site adjustment is required no matter what kind of liquid is measured.

● Suitable for the measurement of liquid, powder and small particle solids.

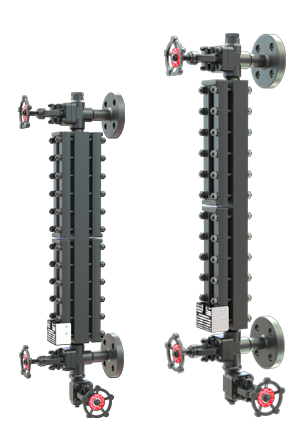

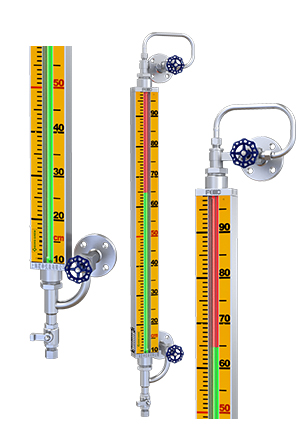

● UHZ-517 Series Magnetic Flap Level Gauge

UHZ-517 series magnetic flap liquid level gauge is a new type of on-site display instrument. The product has the characteristics of simple structure, intuitive and novel reading, no blind spot in observation, large measurement range, safety and reliability, and convenient installation, use and maintenance. This product is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, pharmaceutical, papermaking, environmental protection and other industries to provide on-site indication of the liquid level in various storage tanks, tanks and other containers, and the company’s production All kinds of liquid level transmitters and liquid level switches realize the automatic process control and measurement of various industries.

Features:

● Simple structure, intuitive and novel readings, no blind spot in observation, large measurement range, safe and reliable, easy to install, use and maintain.

● The float is made of 304, 316L, TA2 and TC4 materials, and the float has good high temperature resistance, up to 450°C.

● The welding process meets the requirements of PED welding process. The outer cylinder is made of 304 and 316L materials, and the maximum pressure resistance can reach 26Mpa.

● Optional local indication type, remote transmission type, and liquid level alarm type.

● According to customer needs, through various types of production, it can be applied to various working conditions.

中文

中文