INDUSTRIES

-

A good start to the new year! my country’s second Hualong No. 1 nuclear power unit connected to the grid for power generation The second unit of Hualong No. 1 demonstration project successfully critical For the first time in our country! CNNC’s “China Core” project won the International Quality for Sustainable Development Award People’s Daily: Actively, Safely and Orderly Develop Nuclear Power

ABOUT US

SHANGHAI XINGSHEN INSTRUMENT CO.,LTD.

The XINGSHEN company specializes in R&D, manufacturing, and sales of various level, pressure, and temperature flow instruments for Shenhua Ningxia Coal, China Coal Yulin, China Nuclear Power, PetroChina, Sinopec, and CNOOC...

TEL:+86-021-58308800 E-MAIL:foxc@xingshen.com

MoreSERVICE

SHANGHAI XINGSHEN INSTRUMENT CO.,LTD.

The XINGSHEN company specializes in R&D, manufacturing, and sales of various level, pressure, and temperature flow instruments for Shenhua Ningxia Coal, China Coal Yulin, China Nuclear Power, PetroChina, Sinopec, and CNOOC...

TEL:+86-021-58308800 E-MAIL:foxc@xingshen.com

MorePRODUCTS

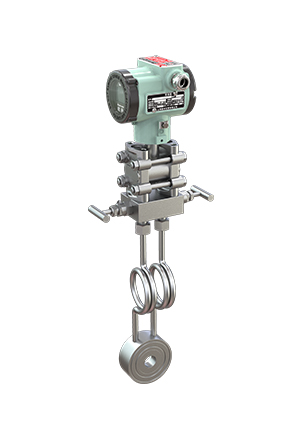

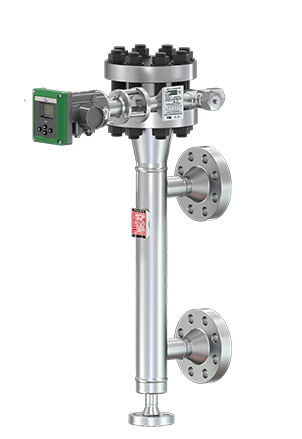

Intelligent Buoyancy Liquid Level Transmitter

LEVEL INSTRUMENT

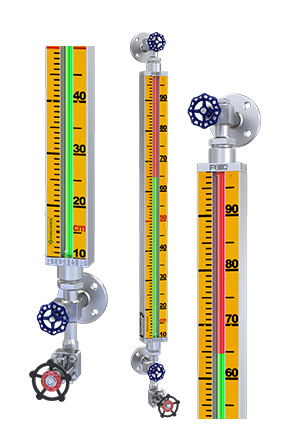

Guided wave radar level gauge

LEVEL INSTRUMENT

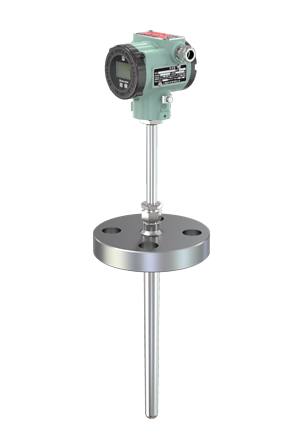

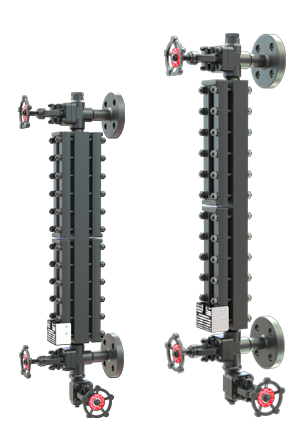

High temperature and high pressure type

LEVEL INSTRUMENT

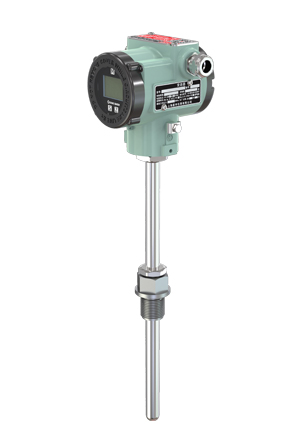

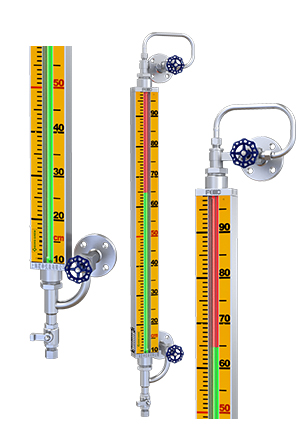

Standard type

LEVEL INSTRUMENT

Tuning fork liquid level/material level switch

LEVEL INSTRUMENT

Industrial Pressure Transmitter

PRESSURE GAUGE

Pressure (Differential Pressure) Transmitters

PRESSURE GAUGE

Hydrostatic Level Transmitter

PRESSURE GAUGE

Pressure gauge

PRESSURE GAUGE

SHANGHAI XINGSHEN INSTRUMENT CO.,LTD.

中文

中文