The R&D team of Shanghai Xingshen broke through the boundary buoy transmitter of the steam and kerosene hydrotreating unit of the coking unit of the centralized processing of crude oil and the structural adjustment of oil refining project.

PetroChina Fushun Petrochemical Company’s 10 million tons of oil refining and 1 million tons of ethylene project is an important project for the country to revitalize the old industrial base in Northeast China. It is also the largest refining and chemical integration project in Northeast China.

The construction of Fushun Petrochemical’s 10-million-ton oil refinery and one-million-ton ethylene project will help PetroChina realize the optimal allocation of crude oil resources in Northeast China, promote the optimization and structural adjustment of refining and chemical business layout, accelerate the implementation of the three strategies of resources, market and internationalization, and improve the Group’s comprehensive economic strength. The implementation of this project is of great significance for transforming the resource advantages of Northeast China into economic advantages, promoting the economic transformation of Fushun City, promoting the economic development of Liaoning, and creating a harmonious economic and social environment.

However, the construction time of this project is very tight, and the task is very heavy. We, Shanghai Xingshen Instrument Co., Ltd. are also honored to participate in the bidding for the supporting instrument frame.

Among them, the boundary buoy transmitter of the crude oil centralized processing and refining structure adjustment technical transformation project coking unit steam and kerosene hydrotreating unit has overcome many technical difficulties, and has been approved by the designer Qilu Petrochemical Engineering Co., Ltd. and PetroChina Fushun Petrochemical Company. unanimously approved. The two measured liquids are residual oil and water, the densities are 0.947 kg/m3 and 0.993 kg/m3 respectively, and the density difference is only 0.046 kg/m3. According to the procurement practice of CNPC, all imported buoys are purchased. The price of the float transmitter is as high as 200,000 to 300,000 yuan, and the delivery cycle is long, and the after-sales service is delayed. This will not only increase the purchase cost, but also delay the start-up time of the original device.

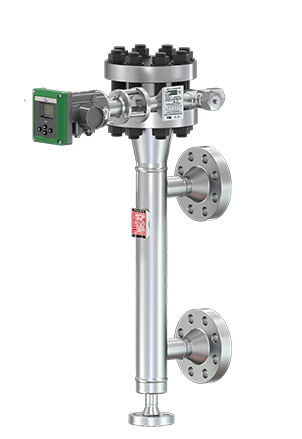

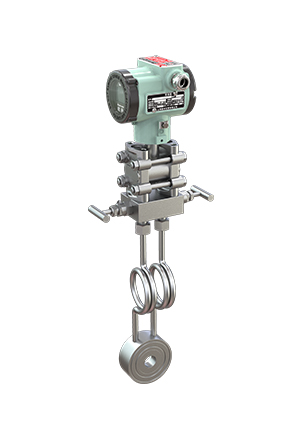

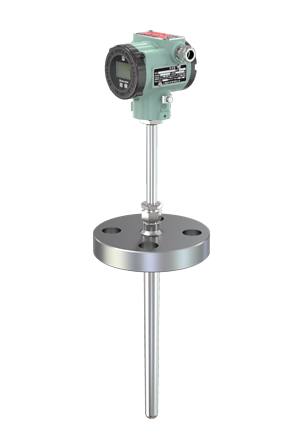

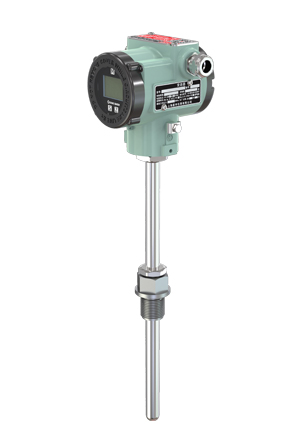

In the supplier inspection in the early stage, our company’s LC3144LD intelligent displacer liquid level (interface) transmitter left a deep impression on the inspection team of Fushun Petrochemical Company. LC3144LD intelligent displacer liquid level (interface) transmitter is a product jointly manufactured by Shanghai Xingshen Instrument Co., Ltd. and Invensys Process Systems (FOXBORO/ECKARDT company). The meter head and key components are original products provided by FOXBORO/ECKARDT. The whole machine is delivered according to the original standard of ECKARDT. LC3144LD intelligent displacer liquid level (interface) transmitter is designed according to the principle of Archimedes, and is used to measure the liquid level, interface and density of liquid. With high measurement stability, it is especially suitable for liquid level/interface measurement occasions with small range, high temperature, high pressure, and low density, and can meet the interface measurement with small medium density difference. The transmitter can communicate through HART protocol.

After the detailed technical communication between the director of Qilu Design Institute and the person in charge of Fushun Petrochemical Instruments and our company, it is recognized that the technical content of our company’s interface transmitter has reached the world’s high-end level, and we are fully capable of providing qualified interface transmitters.

The device was successfully started up once. As a result, we are also honored to be the designated supplier of the upper boundary transmitter for the Fushun Large Ethylene Project, which not only saves costs for Fushun Petrochemical Company’s 10 million tons of oil refining and one million tons of ethylene project, but also ensures the construction period. Also won the reputation for our company.

中文

中文