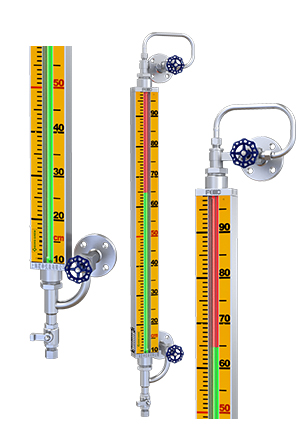

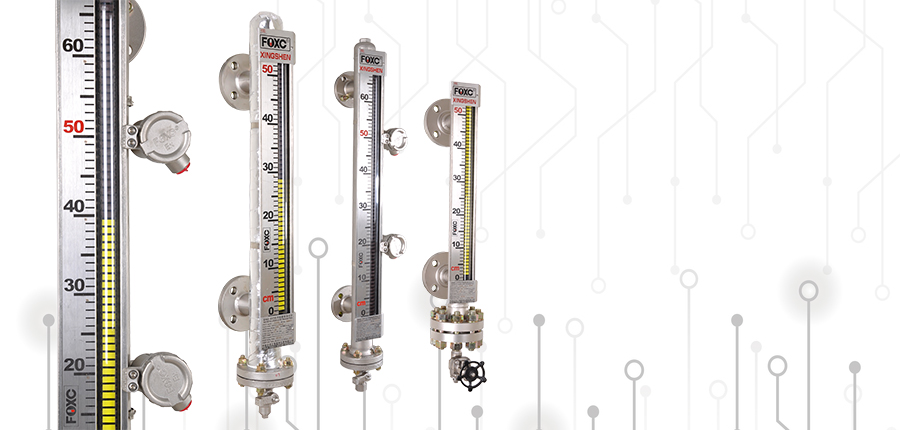

Liquid level gauge is a common instrument in the industrial field, which mainly measures and detects various data. Commonly used liquid level gauges include radar level gauges, magnetic flap level gauges, magnetic flip column level gauges, and magnetic level gauges, float Ball level gaugeMetal tube father-son flowmeter and other instruments and equipment.

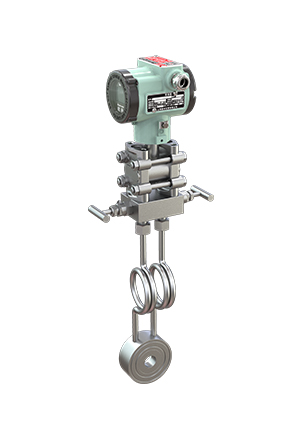

With the development of industry, higher requirements are put forward for these instruments. Generally, due to the complex objects of liquid level measurement and the large changes in the measurement range of liquid level, the factors that need to be considered in the selection process of liquid level gauge mainly include measurement working condition analysis, medium characteristic analysis, measurement requirement analysis, accuracy requirement analysis, user Consideration of usage habits, cost-effective selection, etc. The petrochemical plant has the characteristics of high temperature, high pressure, flammability and explosion. For the instruments used to measure flammable, explosive, toxic and corrosive media, the focus should be on the measurable range, stability, corrosiveness of the medium, and maintenance of the instrument. and so on.

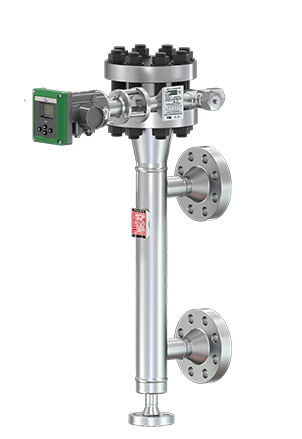

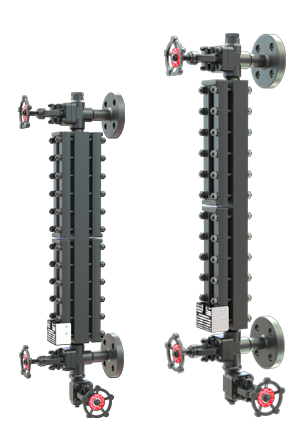

There are many kinds of instruments for liquid level measurement, Magnetic liquid level gauge has the characteristics of high measurement accuracy, wide range, convenient use and low maintenance cost, and can be widely used in petrochemical, pharmaceutical, water conservancy and other fields. Measurement systems such as traditional pressure, mechanical, capacitive, ultrasonic or radar have higher application and economic value. ,Magnetic liquid level gauge refers to the phenomenon that the change of the magnetization direction in the ferromagnetic material will cause the change of the lattice spacing of the medium, so that the length and volume of the ferromagnetic material will change.

中文

中文